Secured Bays & Seismic-Resistant Pallet Racks: Custom Storage for a Gas Company in St. Louis

Posted by Audrey Hood on 31st Oct 2024

Challenge

One company, two warehouses, three storage solutions.

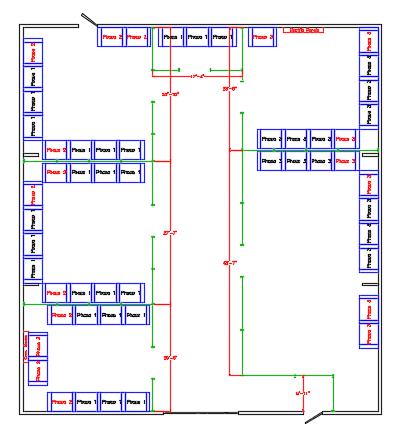

A utility company in St. Louis was in need of several storage solutions for their two warehouses. To start, their first warehouse space needed to be allocated into sections for each department. This company wanted each department to have their own separate storage space, and each needed to be locked and secured. Then, within each bay, departments required racking to store their inventory. The inventory came on pallets in various heights, making standard warehouse storage shelves inefficient for maximizing space.

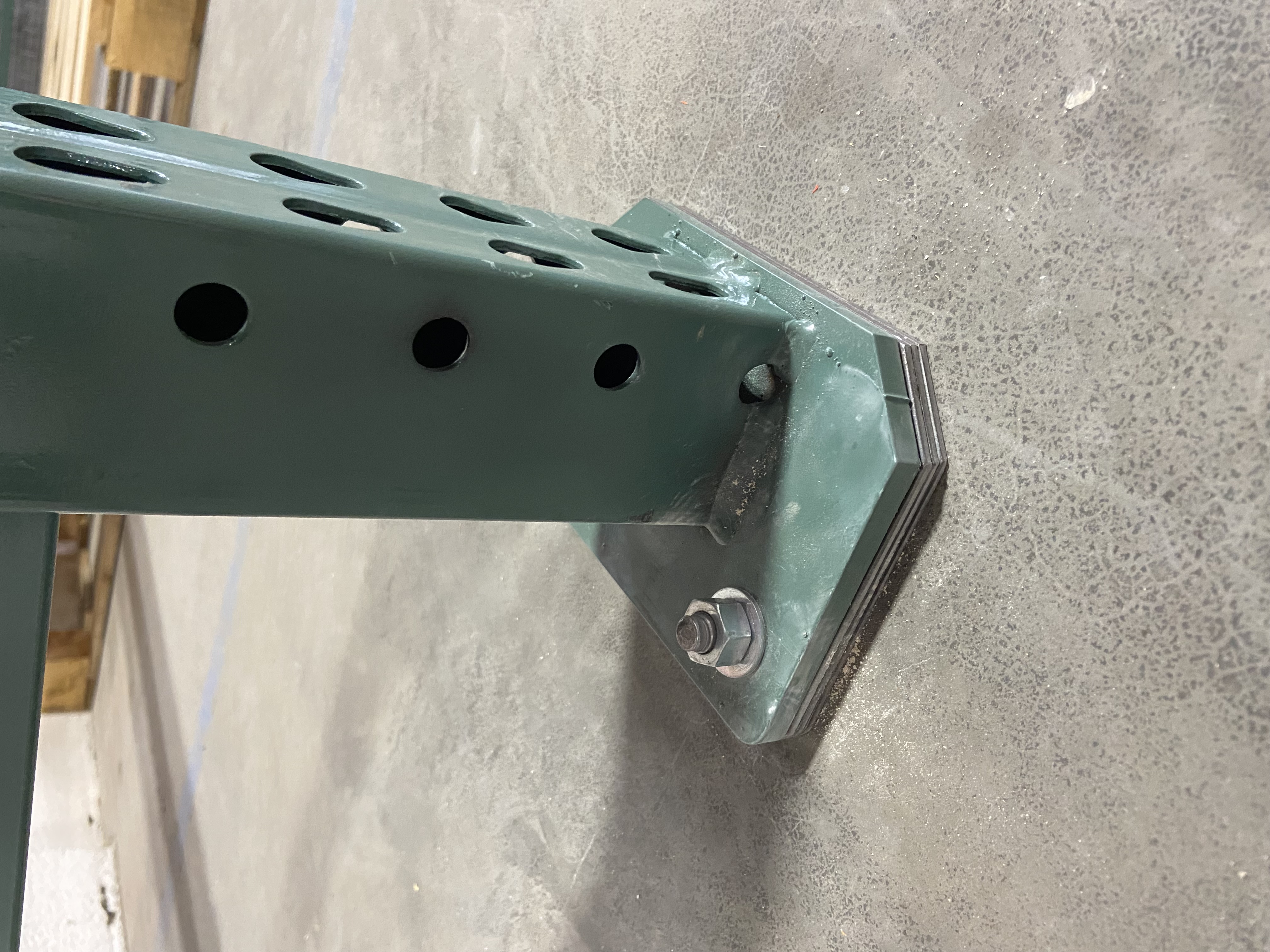

In another warehouse, this customer had a more standard mix of pallet heights needing to be stored. Due to being in a seismic zone, the pallet racking needed to be designed and manufactured to withstand seismic activity. With any racking, it's essential that these heavy-duty industrial racking units be secured to the ground using concrete wedge anchors, preventing movement or potential toppling.

|

||

|

|

|

Solution

Tom from Industrial Shelving Systems led the project and began by measuring the first warehouse space to allocate each area for a different bay. These bays were separated with wire partitions from WireCrafters, each with a lock on the door to ensure security. This sturdy wire partition protects inventory from unauthorized personnel and prevents accidents from improper handling. It also ensures inventory is accounted for, with only employees able to access these bays.

|

|

In Warehouse #1, we installed Vidmar adjustable racking to accommodate pallets of various heights, maximizing storage space by eliminating wasted air space. Unlike standard racking with fixed beam levels, these adjustable racks allowed us to fully utilize space, ensuring all inventory had designated storage without wasting space on items with different heights.

|

|

In Warehouse #2, where the pallet heights were more standardized, Steel King’s Engineering Team specified 5”x7” baseplates due to the seismic zone. Steel King's uprights, with closed-tube designs, offer superior impact resistance compared to open-back racking. To ensure stability, metal shims were used to level the racking. If you’re in a seismic zone or want to check, see our blog here about seismic activity and pallet racking.

|

|

Results

These warehouses are ready to operate with secure shelving systems and heavy-duty storage racks. Now, each department can retrieve inventory efficiently, accelerating operations and improving customer satisfaction.

At Industrial Shelving Systems, our priority is ensuring your operations are as efficient as possible to deliver quick results to customers. Reach out to us here if you have questions about industrial shelving or want to discuss projects to boost operational efficiency. ISS offers a range of storage systems to increase efficiency.

US Dollar

US Dollar