Trends and Innovations for Warehouse Pallet Racks That Are Transforming Storage Solutions

Posted by Audrey Hood on 28th Jan 2025

In today’s fast-paced world, modern logistics are constantly evolving in order to best serve an efficient warehouse solution. A well-organized operation with a solid system in place is the backbone of a smooth, reliable workflow. As businesses grow and customer expectations for quick delivery times intensify, pallet racking solutions have had to evolve to meet these changes.

Alongside having efficient solutions, warehouse operations face increased pressure to implement sustainable practices, making eco-friendly efforts more critical. In this blog, we’ll explore the emerging trends and innovations that are shaping the future of industrial pallet racks, from implementing efficient practices to environmentally friendly solutions.

High Density Industrial Pallet Rack Storage

Most warehouses have been affected by the rise in demand, forcing their operations to handle more inventory with the same amount of space. This challenge has pushed the need for efficient industrial pallet rack setups that maximize available storage room. To ensure that warehouses can keep functioning properly, we’ve seen the use of high-density pallet racking systems more frequently.

One highly efficient industrial pallet rack system is pushback racking . Pushback racking is a shelf system that stores pallets 2 to 6 pallets deep, using a Last-In, First-Out (LIFO) inventory method. This pallet rack system is particularly beneficial for operations that have non-perishable products (where product rotation isn’t critical) and an operation that has multiple pallets of the same SKUs. This allows these same SKU pallets to be stored multiple pallets deep in each lane without the need for an aisle in between them. Using a fork truck, pallets are placed on carts that rest on an inclined lane. When unloading, the pallet behind the one being removed comes to the front of the rack via gravity. Pushback racking has 90% more storage density than the standard racking system. This makes it ideal for managing a growing inventory that needs a high-density industrial pallet rack solution.

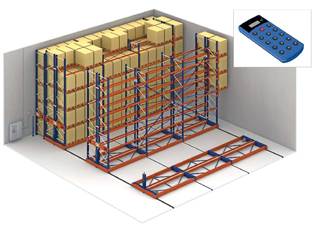

Another excellent high-density solution is mobile racking . This system features a mobile base that allows for racks to move on a track operated by a powered control. Unlike traditional setups, these warehouse pallet racks require only one aisle in between due to the mobile base. This flexibility allows for more space, enabling high density storage. This system is also great for growing operations as additional racks can easily integrate into the current layout.

Pallet flow racking is another great option for warehouses seeking high-density storage. Designed to hold 2-20 pallets in a single lane, pallet flow racking ensures efficiency. These systems allow for a simplified and quick picking process. When one pallet is unloaded, the pallets behind it slide forward, streamlining workflow for warehouse workers. For a warehouse needing speed, this is a great design for industrial pallet racks.

Automated Pallet Racking System

As inventory grows to accommodate increased demand, managers must adapt pallet racking systems to become more efficient.

One great automated material handling system to take the place of traditional pallet racks is an Automated Storage and Retrieval System (AS/RS). AS/RS pallet storage uses shuttles, carousels, and vertical reciprocating conveyors to store, pick, and present pallets or totes. Since this automation solution picks and stores the inventory, these pallet racks can be built much higher than manual operations would allow, making the most of vertical space. This solution also uses floor space much more efficiently as aisles can be closer together compared to the typical setup.

AS/RS is also great for reducing warehouse injuries that could result from workers moving heavy inventory and working with forklifts. Additionally, the AS/RS has remarkable precision with a 99% accuracy rate in picking, eliminating costly picking or replenishing mistakes.

This material handling solution incorporates security measures. As this system has restricted secure access, locked from anyone who is not an authorized administrator, inventory is safeguarded from theft. Apart from security measures, AS/RS systems reduce accidental and environmental damage to your product. With the automation system in place, there is less of a chance for items to drop and become damaged.

Sustainability and Eco-Friendly Designs in Pallet Racking

As sustainability has become such an integral part of operations across the United States, eco-friendly practices have started making their way into systems for industrial pallet racks. Customers increasingly value companies that take on sustainable measures, meaning operations have had to consider how they can reduce their carbon footprint.

One-way warehouses are contributing to green initiatives are with energy efficient designs. For example, cold storage designs require more energy to keep inventory cold. With a high-density pallet rack design, energy can be kept down. Mobile racking, pallet flow racking, and pushback racking are great options for cold storage solutions as they enhance high-density storage.

Some manufactures have also started using eco-friendly material for pallet racking. This helps reduce the carbon footprint while also still creating a high-quality structure that will last. Sourcing high quality warehouse pallet racks can also reduce the frequency of replacing the structure, minimizing waste.

What To Expect in the Next Few Years

As we move into 2025 and beyond, these trends and innovations shaping warehouse operations will become more apparent. To meet the growing demand for supplies, companies will be needing more efficient and high-density designs that can streamline workflow. Automation solutions will continue gaining traction, assisting warehouse workers with heavy labor. At the same time, a rise in green initiatives will push warehouses to implement sustainable practices.

These advancements have the potential to transform warehouse operations. We encourage you to evaluate your current warehouse system and explore opportunities that can help you stay ahead in your industry.

Industrial Shelving Systems and our automation division, ISS Material Handling are here to provide assistance with your pallet racking needs. Be sure to reach out to us if you have any questions or want to find out how a change in your system for warehouse pallet racks can make a difference. Let’s work together to position your operations for success!

US Dollar

US Dollar