What is Mobile Racking?

Posted by Audrey Hood on 4th Oct 2024

Every facility has unique storage requirements and different operational needs. Some warehouses may move items around frequently and others may manage a wide variety of inventory. Regardless of how your operations are structured, one thing remains constant, the need for a solid warehouse shelving system. In this blog, we’ll take a closer look at one type of warehouse pallet rack, mobile racking, and how this can improve efficiency.

What is a mobile racking system?

Mobile racking is a heavy duty racking system that allows for high-density storage with easy access to the pallets. These industrial shelving solutions are great for optimizing floor space, efficient picking, and improved inventory management.

How does mobile racking work?

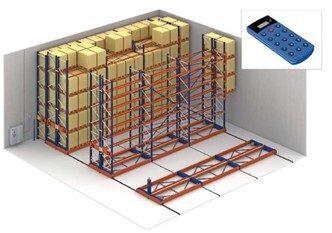

While the name might suggest that the racking itself is mobile, the shelving remains static. The base is what makes these industrial rack systems mobile. The bases on these industrial storage racks move on tracks with either a mechanical assist or powered controls. Powered controls could be a remote control, button control, or touch screen, which an operator uses to move the racks around.

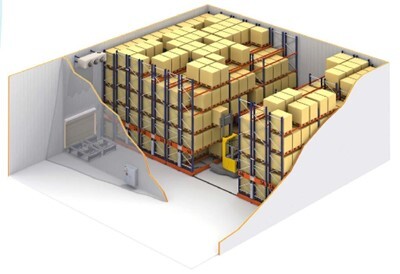

In terms of loading and unloading, pallet racks on mobile racking are moved similar to standard selective pallet racking . The pallets are placed on static beam levels in the racking bay, leaving them secure.

What are the main benefits of mobile racking?

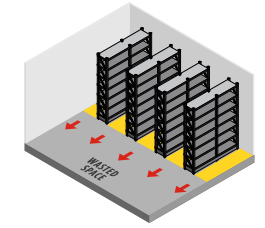

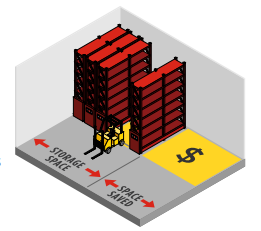

This heavy-duty storage rack allows for high-density storage, significantly saving valuable floor space. Since the base moves, only one aisle is needed as opposed to standard racking where there is an aisle in between each row of racks. As pictured below, you can see that with a fixed aisle setup, more floor space is being used in comparison to the mobile racking.

This single aisle design allows for direct access to the items on the pallets. This makes it suitable for picking and providing easy forklift access. If you have several SKUs that you need direct access to, this heavy duty racking would be ideal for that.

Another key advantage of these industrial racks is the ability for customization to meet your specific needs. Depending on the inventory and forklift type, these heavy duty industrial racks can be tailored to optimize your operations. If you expect growth within your operations, it’s simple to add on additional mobile racks to your current structure.

Additionally, since these racks are placed close together, this can act as an energy saver when storing items that need to be of a certain temperature. By optimizing space, there is less volume of air that needs to be cooled down, allowing for reduced energy consumption.

Where should this racking be used?

These heavy duty storage racks are especially good for storing food and beverage, cold storage, agriculture, automotive, manufacturing, pharmaceutical, 3PLs, aerospace, and distribution facilities. A rule of thumb – any products that are stored on standard racking may also be stored on mobile racking.

If these heavy duty racks sound like they will benefit your operations, reach out to the Industrial Shelving Systems team. We’ll analyze your current facility to decide what storage will work best in your facility. From there, we can design and install your new system – helping you every step of the way.

US Dollar

US Dollar