What is Standard Selective Pallet Racking?

Posted by Audrey Goedegebuure on 20th Aug 2024

Pallet racking is a very common storage solution in warehouses as it serves as an efficient and reliable way to hold inventory. Among this storage solution are several different types. We’ll be diving into the specifics of one – Standard Selective Pallet Racking.

Each different type of racking is designed specifically for a certain benefit. In this case, Standard Selective Pallet Racking is a type of storage solution in which one has direct access to all inventory from the aisle. Built with horizontal cross beams connected to vertical uprights, heavy loads are then able to be placed at different heights. Read below to learn more about this pallet storage and how it may be a good option to include in your operations.

What is Standard Selective Pallet Racking?

Standard Selective Pallet Racking is a popular option for storing palletized inventory as it is easily adaptable. Instead of moving pallets around, one is able to have high visibility and access to all pallet racks. This makes it a great option for warehouses with a high SKU count, allowing for efficiency with workers spotting different inventory.

This type of warehouse racking is also highly customizable as it can be designed in different sizes and weight capacities to best meet that needs of the facility that it’s installed in. It is also the cost-effective heavy duty rack shelving option compared to other options.

What are the two main types of Selective Pallet Racking?

There are two main types of Selective Pallet Racking: Roll Form and Structural. Roll Form Pallet Racking is designed from cold-roll formed steel. This racking does not require bolts to attach to the beams, allowing for an easy installation as the beams instead snap into the uprights. Roll Form Pallet Racking often has a capacity of an upwards of 30,000 lbs.

The other type of heavy-duty rack is Structural Pallet Racking, designed from hot-rolled structural steel. It’s strong, allowing for a higher storage capacity than Roll Form and can withstand more damage from forklifts and other objects. Unlike the Roll Form, bolts are used for the beams, which allows for upright capacities of an upwards of 50,000 lbs. This racking option is especially great for cold storage warehouses, food and beverage warehouses, and heavy capacity applications.

How do you layout Selective Pallet Racking?

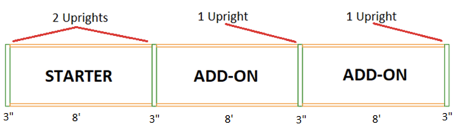

We first begin with ‘starter’ and ‘add-on bays’. The starter bay needs 2 uprights, and then with every bay in the same run, one additional upright is required. See below.

What are the different parts of Selective Pallet Racking?

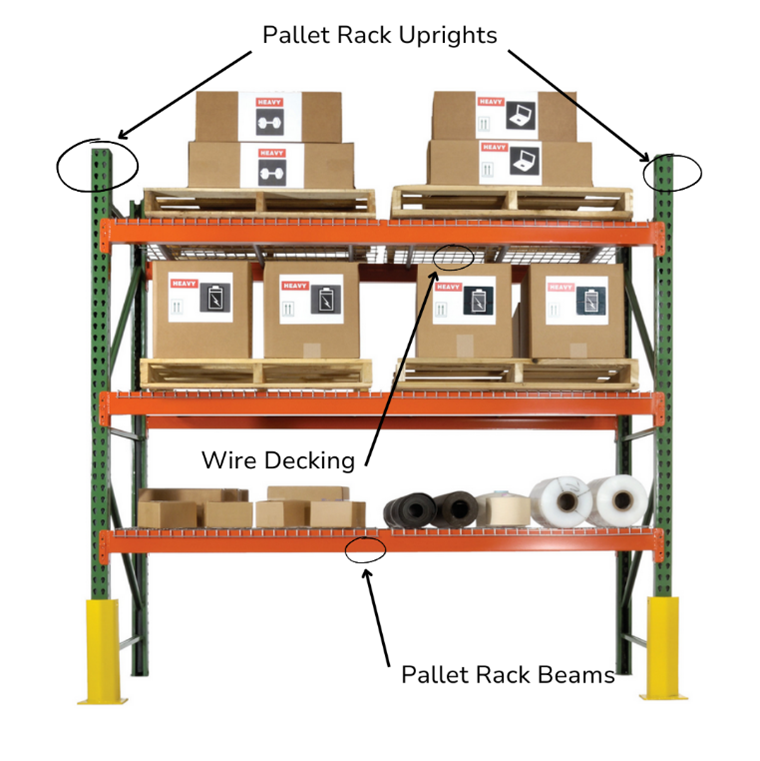

Pallet Rack Uprights are the structural integrity of this warehouse shelving. These vertical frames allow the beams to connect into them, adding stability to the structure. Most common upright frames typically come anywhere from 18” to 48” deep (deeper depths available upon request), and range from 8’ to 30’+ tall. They have a footplate on the bottom of each leg that allows for an anchor to secure the upright into the concrete of the facility.

The Pallet Rack Beams are the horizontal cross bars that carry the weight of the pallet load. Capacities are always listed “per pair”, as a beam is required in the front and the back of the bay for each storage level. Most common beam lengths are 96”, 108”, 120”, and 144”.

Wire Decking is most common and the industry standard when it comes to pallet rack decking. This racking accessory gives you the flexibility to store multiple sized items on each beam level, from cartons to drums. It simply drops into place on a step beam for easy installation with no hardware required. There are support channels welded to the underside of the deck for added strength. It also offers increased fire safety due to the open mesh design. Overall, this is a great way to create heavy duty storage shelves in your facility.

Solid Steel Decking comes either galvanized or with a durable, powder coat finish. It works great for die storage, bagged goods, or any other items that would typically fall through traditional wire deck openings.

Other options also available include corrugated, perforated, and slotted decking. Some end users opt to just have front to back pallet supports, which is acceptable but offers an increased risk of your inventory falling through the storage level. We typically guide people away from wood decking due to the potential fire risks.

Use your vertical space with this warehouse solution! This pallet rack system is a great storage system for your warehouse space as it allows for a high SKU count. Don’t know if this is the right racking for your warehouse storage space? Send our team at Industrial Shelving Systems a message, and we’ll be able to recommend the right storage solution for you.

US Dollar

US Dollar